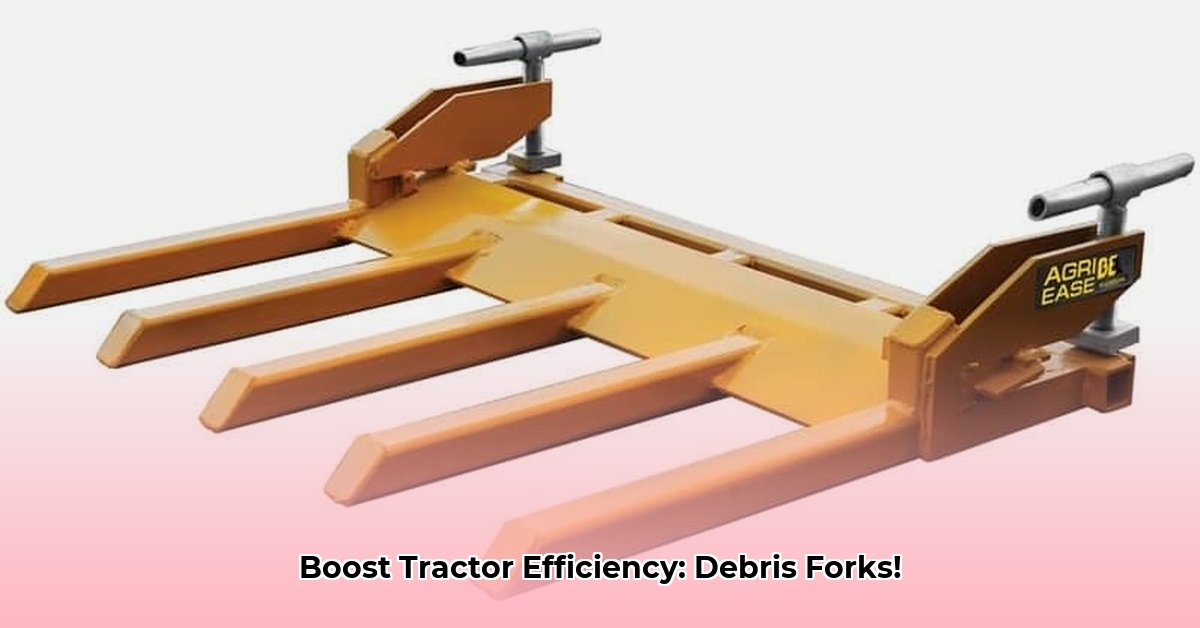

How Debris Forks for Tractors Work: Single vs. Dual Clamp Systems

Debris forks transform your tractor bucket into a versatile tool for efficient material handling. Two primary designs exist: single-clamp and dual-clamp systems. Single-clamp forks utilize a single clamping mechanism, offering simplicity and lower cost. However, this design may place increased stress on the bucket, especially with heavier loads. Dual-clamp systems, conversely, provide superior stability and more even weight distribution, minimizing bucket stress and improving safety, particularly when handling substantial loads. Most debris forks are constructed from high-tensile steel, but the grade and thickness vary significantly among manufacturers and models. The choice between single and dual-clamp systems hinges on the typical weight of materials handled and the operator's prioritization of safety versus cost. Proper selection is essential to avoid bucket damage and ensure safe operation. For more information on debris forks, check out this helpful resource: Learn More.

Market Trends and Choosing the Right Debris Forks

Demand for efficient debris handling solutions is driving significant growth in the debris fork market. Models typically offer lifting capacities up to 2600 pounds. However, a critical market gap exists: a lack of standardized safety regulations across the industry. This disparity necessitates careful research before purchase. Consider factors such as the manufacturer's reputation, customer reviews, and the availability of safety certifications. Compatibility with your specific bucket size (many common sizes are around 48 inches wide) is also paramount. Future trends indicate a probable increase in the use of lighter, stronger materials, possibly including sustainable and recyclable options, to enhance efficiency and reduce environmental impact. Furthermore, advancements in safety features are anticipated, potentially including improved clamping mechanisms and automated safety systems.

Safety Considerations and Regulations

Safety must be the paramount concern when using debris forks. Improper usage or poorly designed equipment can result in serious injury or damage. These critical safety precautions must always be followed:

- Pre-Use Inspection: Thoroughly inspect forks for damage (cracks, wear) before each use; replace or repair damaged components immediately.

- Secure Attachment: Ensure forks are firmly clamped to the bucket before lifting.

- Safe Lifting: Never exceed the forks' or tractor's weight capacity.

- Proper Training: Ensure the operator receives comprehensive training on safe operating procedures.

- Regular Maintenance: Establish and adhere to a regular maintenance schedule.

The absence of industry-wide safety standards underscores the importance of individual due diligence in selecting and using debris forks. Understanding the potential risks and adhering to best practices are crucial for preventing accidents.

Selecting the Right Debris Forks for Your Tractor

Choosing suitable debris forks depends on several factors:

| Factor | Considerations |

|---|---|

| Weight Capacity | Evaluate the heaviest loads you will lift regularly; choose a capacity with a significant safety margin. |

| Bucket Size Compatibility | Precise measurements are essential for a secure fit. Consult manufacturer specifications. |

| Material & Construction | Look for high-quality steel construction, possibly with features like reinforced clamping mechanisms, to enhance durability and safety. |

| Safety Features | Prioritize models with robust clamping mechanisms, secondary safety latches, and clear weight indicators. |

| Price | Balance cost with performance, safety features, and anticipated longevity. |

Maintenance and Best Practices for Debris Forks

Regular maintenance prolongs the lifespan of your debris forks and ensures continued safe operation. Implement these steps:

- Post-Use Inspection: Inspect for damage after every use.

- Lubrication: Lubricate moving parts to reduce wear and tear.

- Repair/Replacement: Promptly repair or replace damaged components.

- Storage: Store forks in a clean, dry location to prevent corrosion.

Proactive maintenance is key to maximizing the return on investment and minimizing the risk of accidents.

Conclusion

Debris forks significantly enhance the efficiency of tractor-based material handling. However, the lack of consistent safety standards underscores the need for careful selection and diligent maintenance. Prioritizing safety, understanding the nuances of different designs, and adhering to best practices are essential for maximizing both productivity and safety. The future of this market will likely involve increased standardization, improved safety features, and the integration of sustainable and environmentally friendly materials.